In the 1950’s, Bomas helped shape the ceramics machining industry.

Today, we are the shape of things to come!

Bomas is credited with being pioneers in the use of Diamond Tooling; and innovators of Conformal Grinding and Machining. Today, our skills, processing decisions, and tooling methods continue to prove unequaled as we master the test of time.

OD Grinding

Tensile specimen with gauge section longitudinally ground; and compression specimens showing OD grinding capabilities

Slotting and Notching

Silicon carbide fixtures showing Diamond Notching and Slotting capabilities

ID / OD Grinding

Inside Diameter and Outside Diameter grinding capabilities to all precision requirements

Diamond Core Drilling and Grinding

Core drilling parameters and grinding shape generation based on your material and exact specifications

Notching and Centerless Grinding

Notching and Centerless Grinding from small diameters to large diameters

Grinding and Slotting

Tapered angle grinding and slotting in rods and tubes at various lengths.

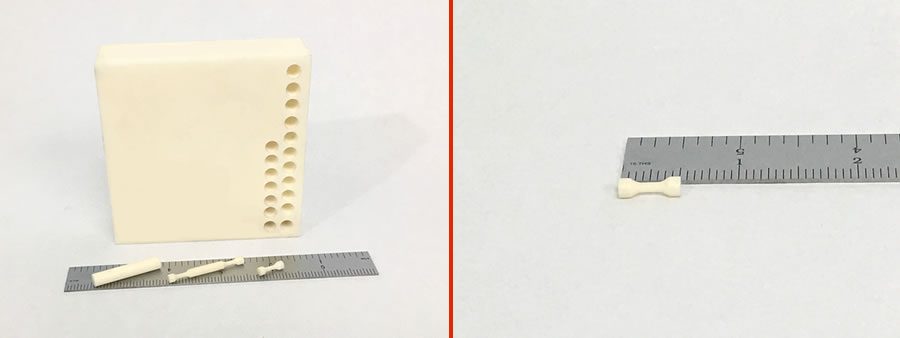

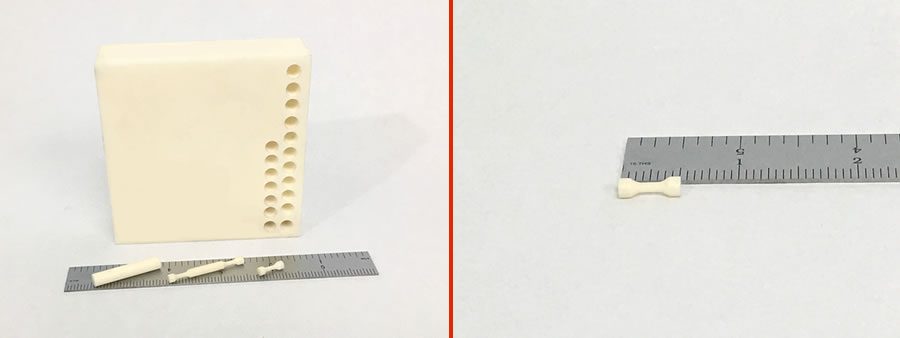

Diamond Core Drilling, Centerless Grinding, Diamond Grinding

Tiny precision machined compression specimen from this alumina ceramic billet in both vertical and horizontal orientation illustrates a process that includes a variety of Bomas skills including diamond core drilling an oversized rod, centerless grinding to major diameter, diamond grinding to finish gauge diameter and gauge length, and diamond slicing – final dogbone is less than 15mm long with extreme care given to parallelism and perpendicularity to finished length dimension – general tolerances are +0/-0.001″

Diamond Core Drilling, OD Grinding, Final Diamond Honing

Silicon Carbide (SIC) Advanced Ceramic Fixture Component demonstrating examples of precision diamond core drilling holes to client specifications, OD grinding, final diamond honing all machined to specific tolerances

Diamond Slicing and Diamond Grinding

Specimens such as these are precision machined from advanced ceramic billets and show process of Bomas diamond slicing and diamond grinding to a square shape, then diamond grinding to an octagon shape to ultimately produce a disc of varying diameters and thicknesses

Diamond Slicing, Diamond Grinding, Slotting, Chevron Notching

Fracture toughness specimens such as these demonstrate Bomas diamond slicing, diamond grinding, slotting, and chevron notching of advanced ceramics

Diamond Core Drilling

This extensometer rod with pin and radiused end are examples of Bomas precise blind hole diamond core drilling and bottoming

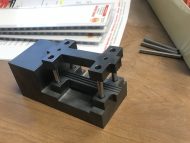

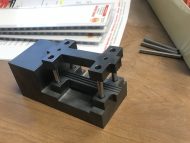

Advanced Ceramic Test Fixture

This intricate test fixture is one of many custom machined fixtures made to exacting client specifications to test advanced ceramic components machined by Bomas