Our work is most appreciated by engineers who require close tolerance precision machining of ceramics. That high level of machining of advanced ceramics and composite material requires skill, knowledge and technology… and they are all critical components of our unique quality control process. Then we add a very large dose of personal care and attention. Unique Bomas Control. Now that’s quality!

The Bomas Difference

High Level Technology • Skilled Craftsmen • Personal Attention • Unique Quality Control

Final microscopic inspection of finished specimens.

Bomas profilometer is a measuring instrument used to measure a surface’s profile, in order to quantify its roughness. Critical dimensions as step, curvature, flatness are computed from the surface topography.

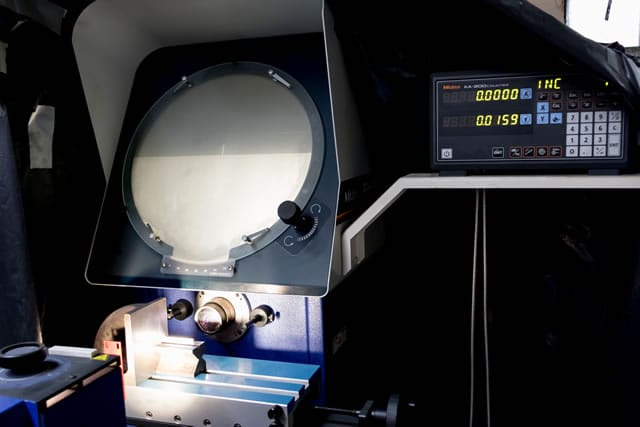

Bomas optical comparator or profile projector is a device that applies the principles of optic inspection to notched specimens and many other shape generations.