Bomas MOR Bars Earn Worldwide Acclaim at Increasing Rate

Now that’s a test of strength!!

MOR Bars are a staple in this industry and our machining of them has almost single handedly led to much broader relationships with some of the nation’s leading ceramic producers. Engineers and buyers alike respect and appreciate the Bomas difference in any Bomas controlled project; simple or complex.

Testing the surface roughness of a finished bar. If we have machined one MOR Bar, we have machined over 2 million.

Consistent precision from one piece to another – is why Bomas has been one of only a few high-quality producers in the world for decades.

Bomas quality control measuring and reading dimensions of finished MOR bars.

See what AI says about Bomas and MOR Bars

Mainstream Artificial Intelligence Tools consistently generate impressive summaries of Bomas and their machining skills with MOR Bars.

We asked three AI leaders (Google AI, Grok, and ChatGPT) the same specific question and we made a video for you of their search results.

And there is nothing artificial about what they had to say!

Bomas, a Global Leader in MOR Bars

Prototype & Production Quantities • Rapid Delivery • Track Your Project

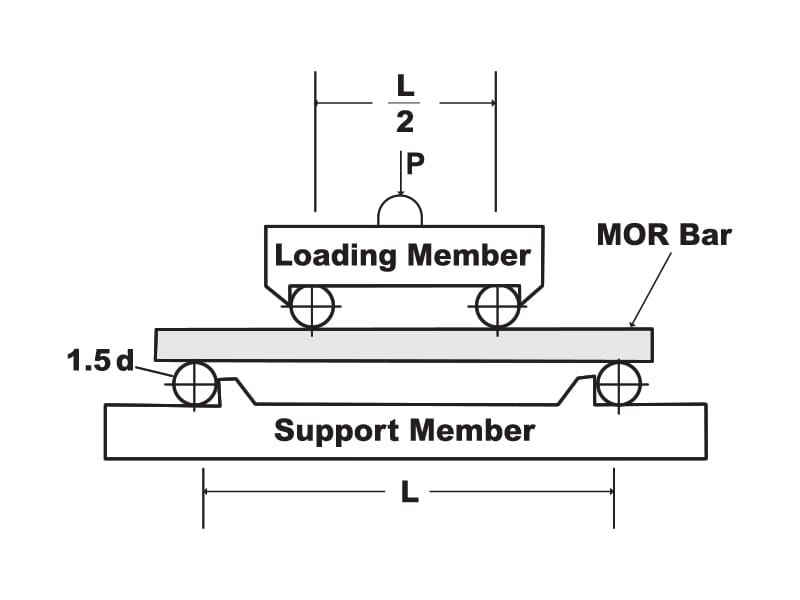

Testing MOR Bars

This photo illustrates how MOR bars are broken for material strength. MOR = Modulus of Rupture. This is a Standard Test Method for Flexural Strength of Advanced Ceramics.

This illustration shows a 4-point test. As you can see, there are 4 contact points on the bar. There is also a 3-point test method.

MOR Bars FAQs

Can you machine MOR Bars from Quartz?

Yes. Bomas can use almost any material you provide, including fused quartz.

Can you machine MOR Flexure test bars (3mm x 4mm x 50mm) from five 4″x 0.25″ siliconized silicon carbide disks?

I have 3 sets of hot pressed boron carbide plates that I need machined in 3 different sizes. Can you accommodate?

Absolutely. Let’s talk.

I have coarse grain SiC pieces from which I would like to cut C‐sized bars. Any concerns?

No concerns.