Bomas Experience Earns Your Trust

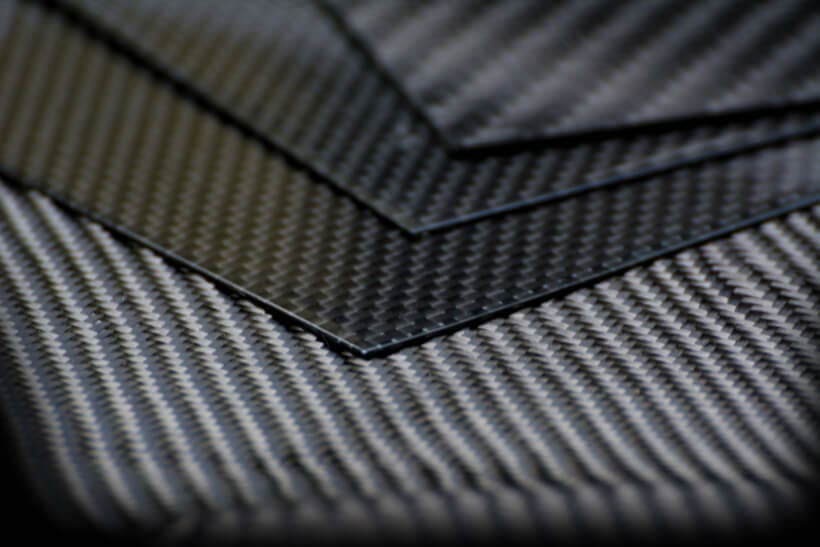

All engineers agree that composites present unique machining challenges. They must protect the integrity of the material and the precision of the final product, all the while safeguarding their capital investment.

And, as a vast legion of engineers agree, Bomas has earned their trust with the machining of their most intricate and delicate designs.

- Precision machining of composite materials and advanced ceramics

- The trusted expertise you require

- Consistency, responsiveness, troubleshooting, and cost savings

- Tooling methods chosen specifically for your unique project

- Legacy of integrity and professionalism

Three generations after its founding, Bomas remains the standard

by which a composites industry of exacting measurements, measures excellence.

Bomas Knowledge Earns Your Confidence

Ceramic Matrix Composites (CMCs) are advanced materials consisting of ceramic fibers embedded in a ceramic matrix. They are designed to overcome the brittleness and low fracture toughness of traditional ceramics like alumina, silicon carbide, or zirconia, which tend to crack under mechanical or thermal stress. By integrating fibers, whiskers, or particles, CMCs achieve enhanced toughness, thermal shock resistance, and durability while retaining the high-temperature stability, corrosion resistance, and lightweight properties of ceramics. You know that. And, as you also know, they are costly materials.

CMCs are used in demanding environments that include all the industries served by Bomas for over six decades, such as Aerospace, Automotive, Energy, Defense, Industrial, Biomedical, Nuclear, and Research Universities.

“Simply put, but for a multitude of reasons, I trust Bomas with my composites machining”.

– Special Products Engineer, for Military Aircraft

You’re visiting this page for a reason.